The Quality Control of Raw Material and Machine Spare Parts

1) All the raw steel and steel plate is for integral cutting to ensure the rigidity and strength of the steel structure. We will make strict raw material inspection before production.

2) The electrical components and spare parts, such as the oil pump, valve, motor etc are world famous brands that imported from Germany, America, Japan and Taiwan to

ensure high quality and long service life of the machine. All of the components comply with CE certification and ISO quality standard.

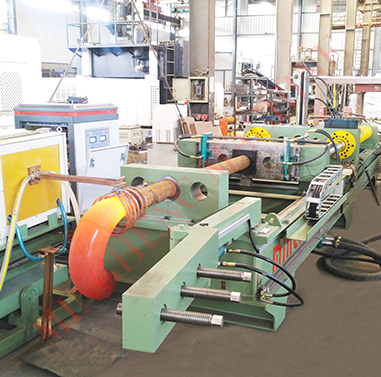

The Quality Control of Heat Treatment and CNC Machining

1) Computer assistant design and stress analysis will be done before production. Full penetration welding of the whole machine steel structure and heat treatment ensure the

high rigidity of the machine body

2) Two times heat treatment ensures the dies and mandrels have perfect hardness. The hardness of the dies and mandrels is up to HRC 52­­­­­-56.

3) Twice CNC machining ensures the high precision of the dies and mandrels.

The Quality Control of Machine Assembly, Inspection and Running

1)Engineers with more than 20 years experience make assembly and testing of the machine.

2)Our machines are designed and manufactured as per customers’ requirements and they can come to check and make pre-acceptance in our plant before shipping.

3)Hardness inspection of dies after heat treatment to ensure perfect hardness and comply with technical standard.

4) Pressure testing of hydraulic system to ensure the pressure of cylinder comply with technical standard.

5)Make the machine test running, testing and inspection of finished elbows, tees etc to ensure the machines satisfy our clients’ technical requirements.

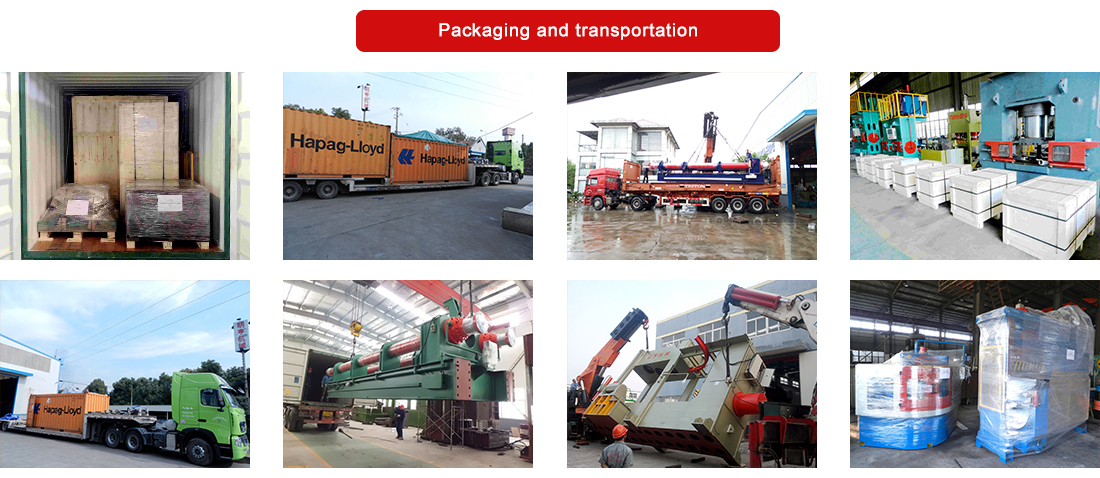

The Quality Control of Packing and Transportation

With rich experience of exporting machinery, we have developed long-term cooperation with some world famous forwarder and ship line companies, such as COSCO,

CHINA SHIPPING, MAERSK, TNT, DHL etc. Therefore, we can offer our customers best delivery plans on time and schedule.

The Quality Control of After-Sale Service

1) We will send our experienced technicians to our customer’s factory for installation and commissioning. During the commissioning, our technicians will train the customer’s

staff to master skills of operating and maintaining the machines.

2) Warranty period is 24 months for machine and 12 months for main parts. If malfunction occurs, we will send our engineer to customer’s factory to troubleshooting if necessary.